Introdução

É bem simples:

- Verifique qual a frequência de lubrificação de acordo com o uso do veículo;

- Use a graxa certa;

- A limpeza é *fundamental*;

- Engraxar;

- Resolver problemas

Peças

-

-

Série SPL:

-

Urbano: 40.000 km ou 6 meses.

-

Rodoviário: 40.000 km ou 6 meses.

-

Agrícola e Construção: 20.000 km ou 3 meses.

-

Industrial: 500 horas em uso normal ou 250 horas em uso severo.

-

Caso o cardan fique imerso em água ou lama (ao enfrentar enchentes, atravessar riachos, trabalhar em arrozais, entre outras situações parecidas), refaça a lubrificação.

-

-

-

A maior causa de problemas em cruzetas e juntas deslizantes é a aplicação de graxas erradas.

-

A graxa precisa unir três propriedades:

-

1 - Ser à base de sabão de lítio.

-

2 - Conter aditivos para extrema pressão (EP).

-

3 - Ter o grau de consistência NLGI 2.

-

Não tente economizar usando outro tipo de graxa. O prejuízo com o cardan será bem maior.

-

-

-

Antes de iniciar a lubrificação, é preciso:

-

1 - Limpar e avaliar o estado de conservação das graxeiras de cada cruzeta.

-

2 - Conferir se a engraxadeira não tem restos de graxa velha ou de outro tipo de graxa.

-

3 - Em sistemas pneumáticos, verificar se o ar não está contaminado com água ou óleo.

-

-

-

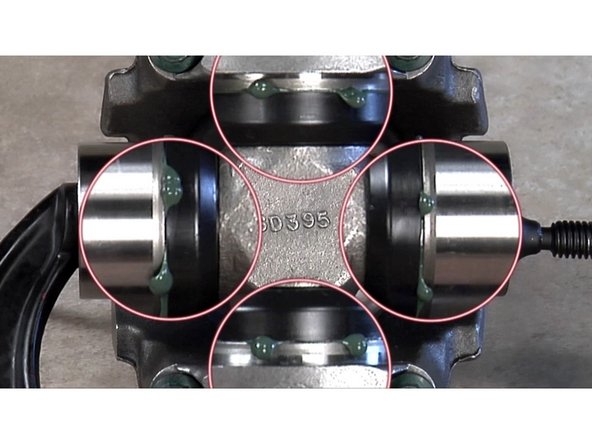

Com tudo em ordem, lubrificar uma cruzeta Spicer SPL170-1XS é muito fácil. Mas um cuidado é fundamental: aplique a graxa nova até que a graxa velha saia completamente das quatro capas da cruzeta. Veja no vídeo ao lado o passo a passo detalhado.

-

Depois, siga aplicando mais um pouco, até que a graxa nova saia de forma contínua das capas, sem falhas ou bolhas de ar.

-

Se der tudo certo, limpe a cruzeta e o serviço estará pronto.

-

-

-

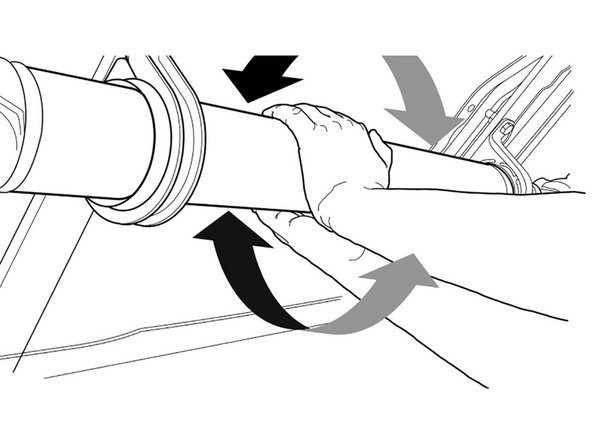

Se alguma capa da cruzeta não purgar a graxa velha, é preciso resolver o problema:

-

Experimente mover o cardan de um lado para o outro, acionando a engraxadeira, como na ilustração.

-

Se for o eixo do garfo que não purga, bata com um martelo de borracha na lateral do garfo para aliviar a pressão de fixação da lingüeta e tente lubrificar.

-

Gire o cardan 180 graus e repita o procedimento no lado oposto.

-

Se ainda assim não ocorrer a purga em alguma das capas da cruzeta, solte os parafusos e retire a lingüeta da lateral do garfo do cardan e faça a lubrificação até obter a purga nas quatro capas. Nessa operação as braçadeiras, parafusos e lingüetas devem sempre ser substituídos.

-

Veja se os canais internos de lubrificação da peça não estão entupidos.

-

Remonte a cruzeta e, com um torquímetro, aperte as abas com um torque de 40 Nm.

-

Refaça o procedimento de lubrificação. Se mesmo assim a capa não purgar, é necessário trocar a cruzeta.

-

Cancelar: não concluí este guia.

2 outras pessoas concluíram este guia.