Introdução

Substituir uma Junta Homocinética Deslizante requer alguns cuidados e ferramentas especificas

Ferramentas

Peças

Nenhum parts especificado.

-

-

Com o veículo apoiado no chão solte a porca do semi-eixo e os parafusos da roda; Com o veículo suspenso, remova a roda;

-

Solte as porcas do pivô e do terminal de direção; Utilizando um Extrator , remova o pivô e o terminal;

-

Remova a bieleta;

-

Com o auxilio de uma alavanca, force a bandeja para baixo para desacoplar o pivô;

-

Puxe a manga de eixo para liberar a Junta Fixa, caso necessite, use um martelo de poliuretano;

-

Utilizando uma espátula, remova a Tulipa do Câmbio;

-

-

-

Remova as abraçadeira da coifa e retire a tripeça da tulipa;

-

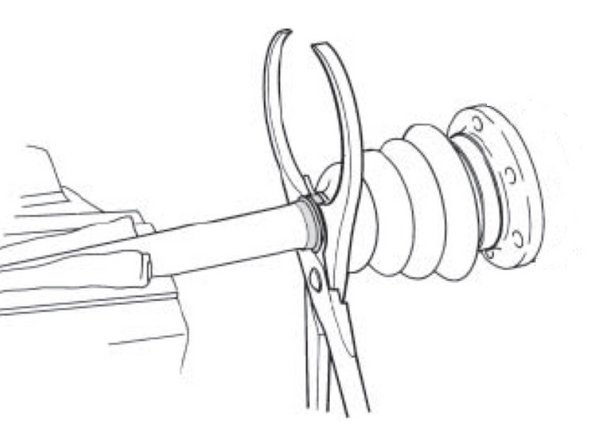

Utilizando um alicate para anéis, remova trava e a tripeça;

-

Limpe o Semi-eixo para evitar a contaminação da graxa.

-

-

-

Monte manualmente a Coifa;

-

Posicione o estriado da Tripeça no estriado do Semi-eixo;

-

Coloque a trava;

-

Encaixe a Tripeça na Tulipa;

-

Coloque as abraçadeiras da coifa.

-

-

-

Encaixe a Tulipa no Câmbio;

-

Coloque a ponta da Junta Fixa no Cubo. Encaixe a Manga de eixo no Pivô. Instale o terminal de direção;

-

Aperte as porcas dos Pivô e do Terminal de direção. Reinstale a bieleta;

-

Coloque a nova porca da Semi-eixo, não reutilize a porca antiga. Posicione a Roda e os parafusos da roda.

-

Com o veículo apoiado no chão, aplique 330 Nm de torque na porca do semieixo, aperte as porcas da roda;

-

Para evitar desaperto acidental, recrave o colarinho da porca do eixo no rebaixo da Junta.

-

-

-

Sob quaisquer circunstâncias deve-se tentar qualquer conserto ou manutenção para o qual não foi treinado ou se não possui as ferramentas e equipamentos para o conserto.

-

Sempre use os óculos de segurança adequado quando fizer algum tipo de manutenção. Não usar os óculos de segurança pode resultar em ferimento e/ou perda parcial ou completa da visão.

-

Seja sempre cuidadoso ao trabalhar com produtos que tenham pontas afiadas.

-

-

-

Parte importante do trabalho e da própria operação da sua oficina é o descarte correto dos produtos que serão substituídos. Faça a sua parte e juntos contribuímos para um futuro sustentável.

-

Saiba mais em http://www.spicer.com.br/danatureza

-

Evite danos e desgastes prematuros, após a instalação do Semi-eixo, verifique a geometria do veículo.

Evite danos e desgastes prematuros, após a instalação do Semi-eixo, verifique a geometria do veículo.