Introdução

Substituir uma Junta Homocinética Deslizante requer alguns cuidados e ferramentas especificas.

-

-

Com o veículo apoiado no chão, solte a porca do semi-eixo e os parafusos da roda; Com o veículo suspenso, remova a roda;

-

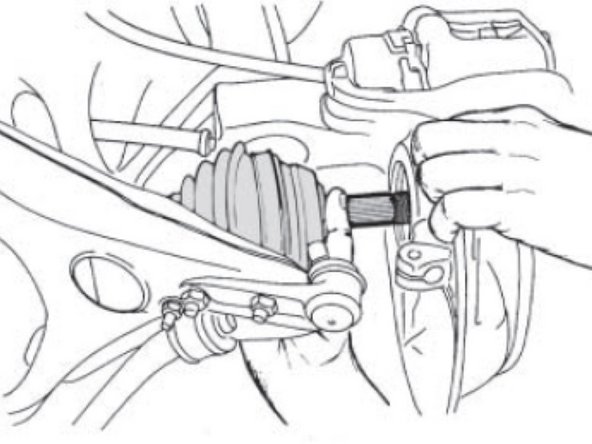

Solte as porcas do pivô e do terminal de direção; Utilizando um Extrator , remova o pivô e o terminal;

-

Retire os parafusos que ligam a torre de suspensão a manga de eixo;

-

Com o auxilio de uma alavanca, force a bandeja para baixo para desacoplar o pivô;

-

Puxe a manga de eixo para liberar a Junta Fixa, caso necessite, use um martelo de poliuretano;

-

Solte os 6 parafusos de fixação da Junta Deslizante da tulipa e remova o semi-eixo do veículo.

-

-

-

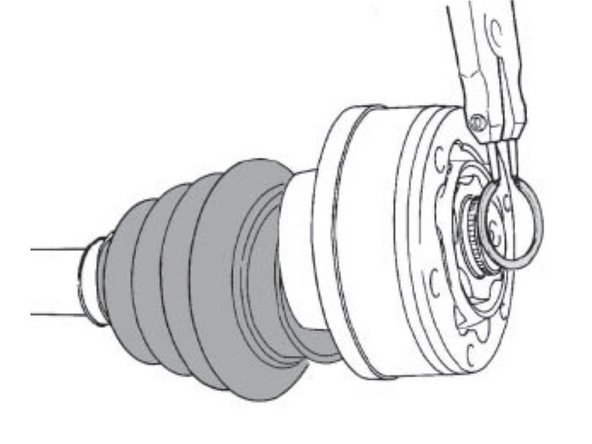

Utilizando um alicate para travas, abra o anel trava e remova do eixo;

-

Remova a Junta Deslizante , a mola prato e a coifa;

-

Limpe o Semi-eixo para evitar a contaminação da graxa.

-

-

-

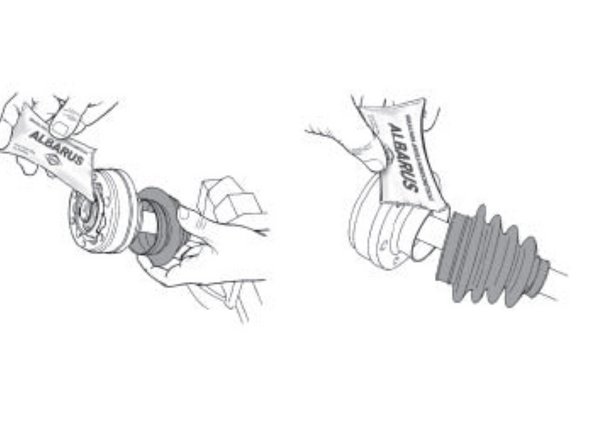

Monte manualmente a Coifa, a junta, a mola prato (com a parte côncava, voltada para o lado de fora da articulação), coloque a vedação entre a flange da coifa e a Junta Deslizante;

-

Encaixe a Junta Deslizante no semi-eixo. Monte o anel trava;

-

Aplique a graxa na Junta Deslizante;

-

Coloque a vedação e a capa na Junta Deslizante;

-

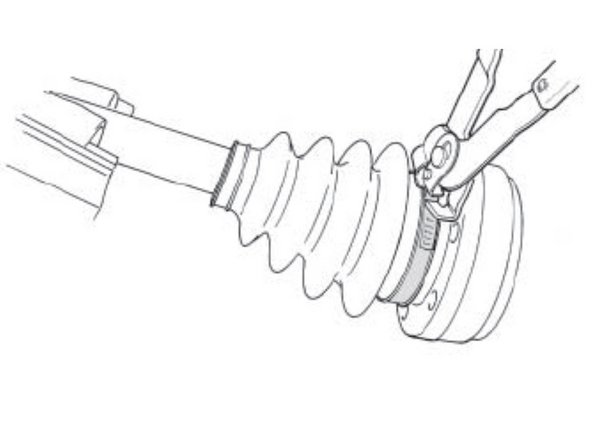

Posicione os parafusos para facilitar o processo;

-

Fixe a abraçadeira maior com o auxilio do Alicate especial; Antes de fixar a braçadeira menor, utilize uma chave de ponta roliça entre a coifa e o eixo pra entrar um pouco de ar. Fixe a braçadeira menor, posicionando no rebaixo do eixo.

-

-

-

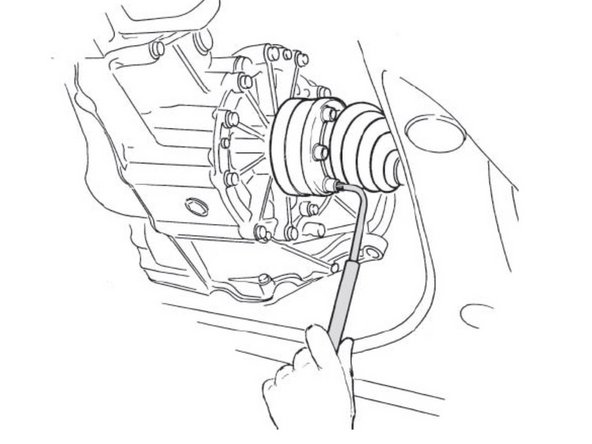

Encaixe a Junta Deslizante na tulipa do câmbio;

-

Aplique 40 Nm de torque nos 6 parafusos de fixação da Junta Deslizante;

-

Coloque a ponta da Junta Fixa no Cubo. Encaixe a Manga de eixo no Pivô e posteriormente os parafusos da torre de suspensão. Instale o terminal de direção;

-

Aperte as porcas dos Pivô e do Terminal de direção.

-

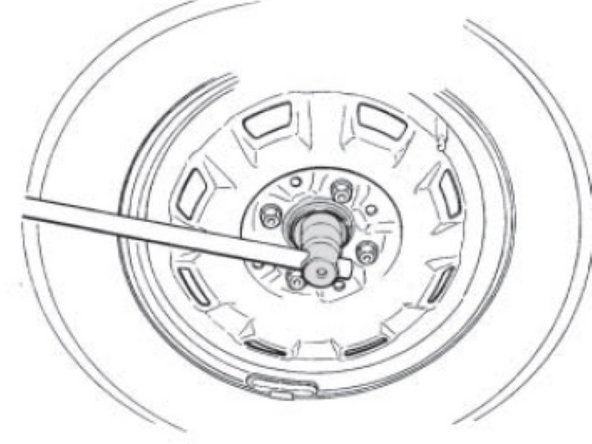

Coloque a nova porca da Semi-eixo. Posicione a Roda e os parafusos da roda.

-

Com o veículo apoiado no chão, aperte as porcas da roda. Aplique 280 Nm na porca do Semi-eixo.

-

Para evitar desaperto acidental, recrave o colarinho da porca do eixo no rebaixo da Junta.

-

-

-

Sob quaisquer circunstâncias deve-se tentar qualquer conserto ou manutenção para o qual não foi treinado ou se não possui as ferramentas e equipamentos para o conserto.

-

Sempre use os óculos de segurança adequado quando fizer algum tipo de manutenção. Não usar os óculos de segurança pode resultar em ferimento e/ou perda parcial ou completa da visão.

-

Seja sempre cuidadoso ao trabalhar com produtos que tenham pontas afiadas.

-

-

-

Parte importante do trabalho e da própria operação da sua oficina é o descarte correto dos produtos que serão substituídos. Faça a sua parte e juntos contribuímos para um futuro sustentável.

-

Saiba mais em http://www.spicer.com.br/danatureza

-

Evite danos e desgastes prematuros, após a instalação do Semi-eixo, verifique a geometria do veículo.

Evite danos e desgastes prematuros, após a instalação do Semi-eixo, verifique a geometria do veículo.