Introdução

A Divisão de Veículos Comerciais da Dana apresenta esta publicação para auxiliar na manutenção e revisão dos eixos de transmissão simples Spicer. As instruções contidas abrangem os modelos listados. Seu design é comum, com diferenças na capacidade de carga. As variações de capacidade são obtidas pela combinação de conjuntos básicos de suporte diferencial com diferentes caixas de eixo, semi-eixos e equipamentos de roda.

Informações gerais

A descrição e as especificações contidas nesta publicação de serviço estão atualizadas no momento da impressão.

A Dana reserva-se o direito de descontinuar ou modificar seu

modelos e/ou procedimentos e para alterar especificações

a qualquer momento, sem aviso prévio.

Qualquer referência a uma marca nesta publicação é feita simplesmente como um exemplo dos tipos de ferramentas e materiais recomendados para uso e não deve ser considerada uma

endosso. Equivalentes, se disponíveis, podem ser usados.

Utilize sempre peças de reposição originais Spicer.

-

-

Este símbolo é utilizado em todo este manual para destacar os procedimentos onde o descuido ou falha em seguir instruções específicas podem resultar em danos pessoais e / ou danos aos componentes.

-

Partida das instruções, escolha de ferramentas, materiais e peças recomendadas indicados nesta publicação pode colocar em risco a segurança pessoal do técnico de serviço ou operador do veículo.

-

AVISO: O não cumprimento dos procedimentos indicados cria um alto risco de ferimentos pessoais ao técnico de manutenção. -

CUIDADO: O não cumprimento dos procedimentos indicados pode causar danos aos componentes ou mau funcionamento. -

IMPORTANTE: Procedimentos altamente recomendados para a manutenção adequada desta unidade. -

OBSERVAÇÃO: Informações adicionais sobre o serviço não abordadas nos procedimentos de serviço. -

DICA: Procedimentos úteis de remoção e instalação para auxiliar na manutenção desta unidade. -

DEM: Consulte as especificações do veículo OEM

-

-

-

Listagem de modelos

-

-

-

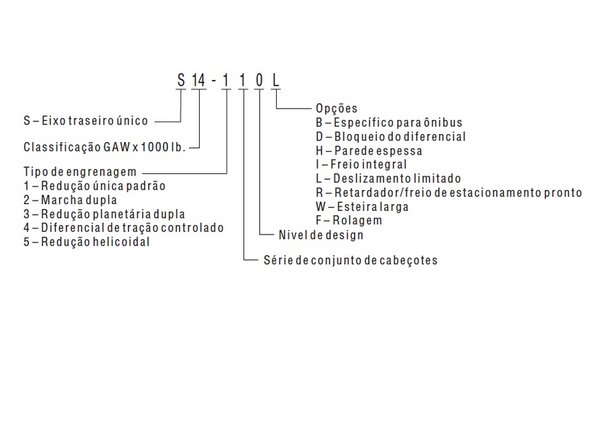

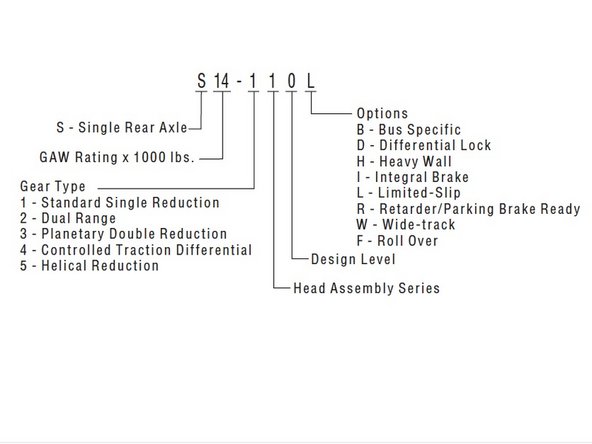

Informações do modelo

-

-

-

Insira tradução aqui

-

Insira tradução aqui

-

Insira tradução aqui

-

Insira tradução aqui

-

Insira tradução aqui

-

Insira tradução aqui

-

Insira tradução aqui

-

-

-

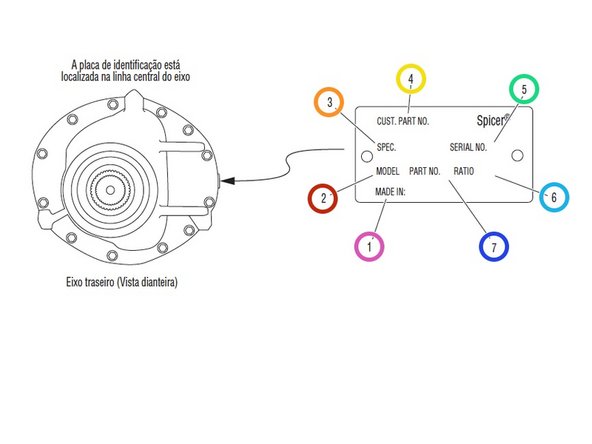

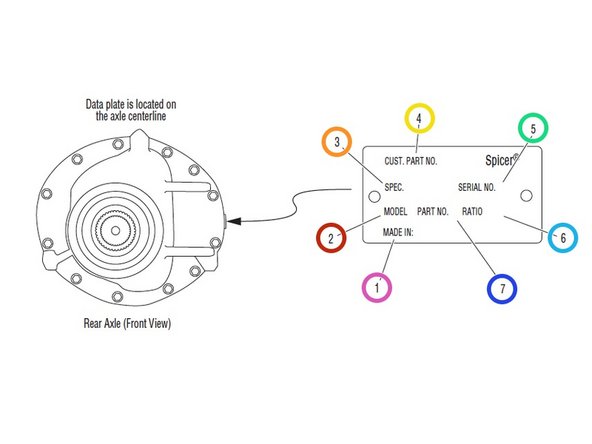

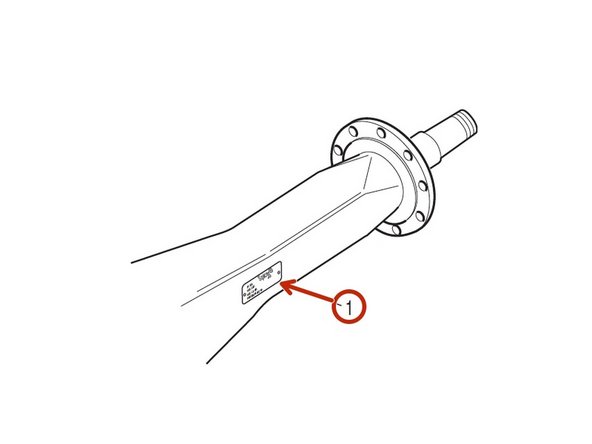

Carcaça do eixo

-

1 - Etiqueta de identificação

-

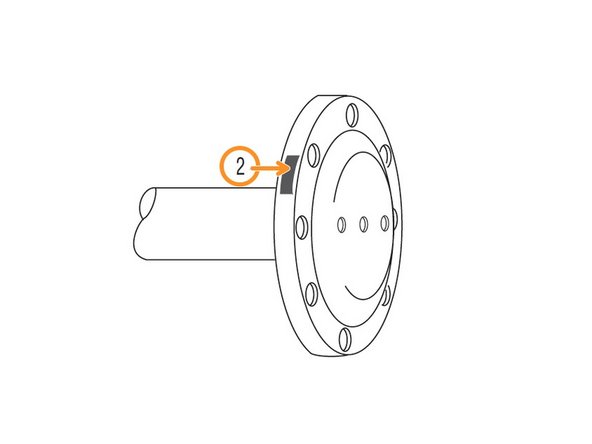

Eixo do eixo

-

2 - Número da peça do eixo

-

-

-

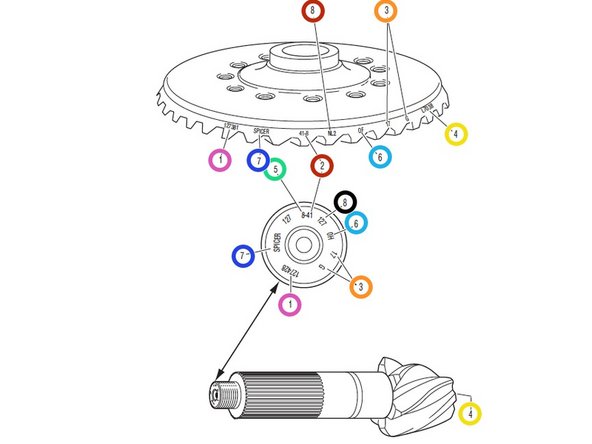

Observação: A engrenagem anelar e o pinhão de transmissão são peças correspondentes e devem ser substituídas em conjuntos. 1 - Número da peça -

2 - Número de dentes da engrenagem do anel

-

3 - números de Fabricação

-

4 - Matching número de engrenagem definido

-

5 - Número de dentes do pinhão

-

6 - Código Data

-

7 - Indica peças Spicer genuínas

-

8 - Código de calor

-

-

-

Análise de falhas é o processo de determinar a causa original de uma falha de componente para evitar que ela aconteça novamente. Muitas vezes, quando um componente com falha é substituído sem determinar sua causa, haverá uma falha recorrente.

-

Se uma caixa de transporte for aberta, revelando uma engrenagem de anel com um dente quebrado, não é suficiente para decidir sobre o dente quebrado como a causa da falha do transporte. Outras partes do transporte devem ser examinadas.

-

Para uma compreensão completa da falha e possíveis insights sobre problemas relacionados, o técnico precisa observar a condição geral do veículo.

-

Ninguém se beneficia quando um componente com defeito vai para a pilha de lixo com causa desconhecida. Nada é mais perturbador para um cliente do que uma falha repetida.

-

Analisar sistematicamente uma falha para evitar que ocorra novamente garante um serviço de qualidade, evitando tempo de inatividade desnecessário e mais despesas para o cliente.

-

A verdadeira causa de uma falha pode ser melhor determinada ao saber o que procurar, determinando como uma parte do equipamento estava funcionando e aprendendo sobre problemas anteriores. No caso de um eixo traseiro reconstruído, engrenagens incompatíveis podem ter sido instaladas.

-

As oficinas mais bem-sucedidas previnem falhas repetidas de equipamentos desenvolvendo boas práticas de análise de falhas. Saber como diagnosticar a causa de uma falha prematura é um dos pré-requisitos de um bom técnico de equipamentos pesados.

-

-

-

As cinco etapas a seguir são uma abordagem eficaz para um bom diagnóstico de falhas.

-

Documente o problema.

-

Faça uma investigação preliminar.

-

Prepare as peças para inspeção.

-

Encontre a causa da falha.

-

Corrija a causa do problema.

-

-

-

Aqui estão algumas diretrizes para começar a aprender sobre uma falha, incluindo perguntas a serem feitas:

-

Fale com o operador do caminhão.

-

Veja os registros de serviço.

-

Descubra quando o caminhão foi revisado pela última vez.

-

Pergunte: Em que tipo de serviço o caminhão está sendo usado?

-

Pergunte: Essa falha específica já ocorreu antes?

-

Pergunte: Como o caminhão estava funcionando antes da falha?

-

-

-

Você precisa ser um bom ouvinte. Às vezes, sintomas insignificantes ou não relacionados podem apontar para a causa da falha:

-

Pergunte: O veículo estava operando em temperaturas normais?

-

Pergunta: Os medidores estavam mostrando faixas normais de operação?

-

Pergunte: Houve algum ruído ou vibração incomum?

-

Após ouvir, revise os registros de reparo e manutenção anteriores. Se houver mais de um motorista, converse com todos eles e compare suas observações para consistência com os registros de serviço e manutenção.

-

Verifique o número de identificação do veículo (VIN) do chassi na placa de identificação do veículo, bem como a quilometragem e as horas do veículo.

-

-

-

Essas etapas consistem em inspeções e observações externas que serão valiosas quando combinadas com os resultados do exame das peças.

-

Procure por vazamentos, rachaduras ou outros danos que possam indicar a causa da falha.

-

Anote vazamentos óbvios ao redor de plugues e vedações. Um plugue de enchimento ou drenagem faltando seria um motivo óbvio de preocupação.

-

Procure por rachaduras no compartimento do transportador (mais difíceis de ver, mas às vezes visíveis).

-

O estado mecânico geral do veículo indica manutenção adequada ou há sinais de negligência?

-

Os pneus estão em boas condições e os tamanhos são os mesmos?

-

Se equipado com um dispositivo limitador de torque, ele está funcionando corretamente?

-

Durante a investigação preliminar, anote qualquer coisa fora do comum para referência posterior. Itens que parecem insignificantes agora podem assumir mais importância quando os subconjuntos forem desmontados.

-

-

-

Após a investigação preliminar, localize a falha e prepare a peça para exame. Na análise de falha do transportador, pode ser necessário desmontar a unidade.

-

Ao desmontar subconjuntos e peças, não limpe as peças imediatamente, pois a limpeza pode destruir algumas evidências.

-

Ao desmontar o eixo de transmissão, faça-o da maneira recomendada. Minimize qualquer dano adicional à unidade.

-

Faça mais perguntas ao examinar o interior do transportador. O lubrificante atende às especificações do fabricante em relação à qualidade, quantidade e viscosidade? Assim que você localizar a peça com defeito, reserve um tempo para analisar os dados.

-

-

-

Aqui começa o verdadeiro desafio de determinar a causa exata da falha. Tenha em mente que não há benefício em substituir uma peça com falha sem determinar a causa da falha.

-

Por exemplo, após examinar uma peça com defeito e descobrir que a falha é causada por falta de lubrificação, você deve determinar se houve um vazamento externo. Obviamente, se houver um vazamento externo, apenas substituir a engrenagem com defeito não vai corrigir a situação.

-

Outra consideração importante é determinar o tipo específico de falha que pode ser um indicador valioso para a causa da falha. As páginas a seguir mostram diferentes tipos de falhas e possíveis causas. Use isso como um guia para determinar os tipos de falhas e corrigir problemas.

-

-

-

Depois que a causa do problema for determinada, consulte o manual de serviço apropriado para realizar os reparos.

-

-

-

Lave peças de aço com superfícies retificadas ou polidas em solvente. Há muitos solventes comerciais adequados disponíveis. Querosene e óleo diesel são aceitáveis.

-

AVISO: A gasolina não é um solvente aceitável devido à sua extrema combustibilidade. Ela não é segura no ambiente da oficina.

-

Lave peças fundidas ou outras peças ásperas em solvente ou limpe em tanques de solução quente usando soluções alcalinas suaves.

-

Se for usado um tanque de solução quente, certifique-se de que as peças estejam completamente aquecidas antes de enxaguar.

-

Enxágue bem para remover todos os vestígios da solução de limpeza.

-

Seque as peças imediatamente com panos limpos.

-

Peças de óleo.

-

Se as peças forem reutilizadas imediatamente: Lubrifique levemente. Se as peças forem armazenadas: Cubra com óleo, embrulhe em papel resistente à corrosão e armazene em um local limpo e seco.

-

-

-

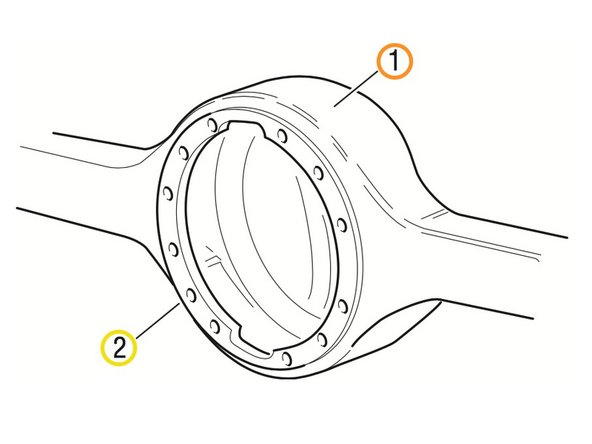

A inspeção e os reparos da carcaça do eixo são limitados às seguintes verificações ou reparos.

-

Inspecione visualmente a carcaça do eixo para verificar se há rachaduras, cortes e rebarbas nas superfícies usinadas.

-

Verifique se há materiais estranhos nos furos e pinos dos parafusos de suporte.

-

Substitua fixadores danificados. Procure por parafusos soltos ou furos com rosca cruzada.

-

Qualquer dano que afete o alinhamento ou a integridade estrutural do alojamento requer a substituição do alojamento. Não repare dobrando ou endireitando. Este processo pode afetar as propriedades do material e fazer com que ele falhe completamente sob carga.

-

Verifique todas as vedações e juntas.

-

Substitua as juntas convencionais por composto de junta de borracha de silicone (incluído em muitos kits de reparo). O composto fornece uma vedação mais eficaz contra vazamento de lubrificante e é mais fácil de remover das superfícies de contato ao substituir peças.

-

-

-

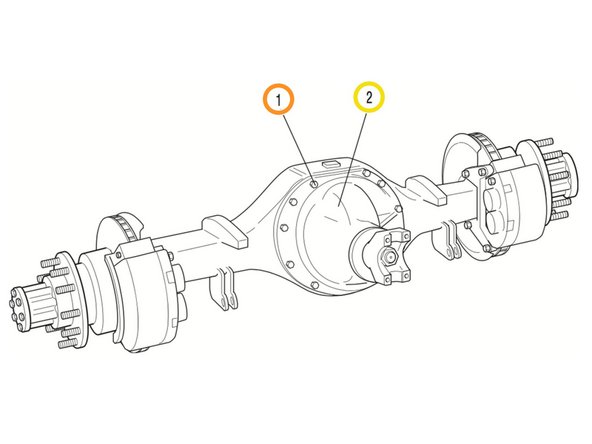

1 - Carcaça do eixo

-

2 - Superfície usinada

-

-

-

Inspecione todas as peças de aço para:

-

Entalhes, degraus visíveis ou ranhuras criadas pelo desgaste.

-

Pontuações ou rachaduras ao longo das linhas de contato das engrenagens.

-

Arranhões, deformações ou descolorações. Esses são sinais de calor excessivo no eixo e geralmente estão relacionados a baixos níveis de lubrificação ou práticas de lubrificação inadequadas.

-

-

-

Além disso, inspecione o seguinte para verificar se há danos:

-

Engrenagem diferencial.

-

Rolamentos para ajuste frouxo no pinhão de transmissão e rolamentos diferenciais.

-

Todos os fixadores para cabeças arredondadas, dobras, rachaduras ou roscas danificadas.

-

Inspecione superfícies usinadas de peças fundidas ou maleáveis. Elas devem estar livres de cortes, rebarbas, rachaduras, escoriações e desgaste.

-

Procure por alongamento de furos perfurados, desgaste em superfícies usinadas para encaixes de rolamentos e entalhes ou rebarbas em superfícies de contato.

-

-

-

Antes de reutilizar um conjunto de engrenagens primárias, inspecione os dentes para sinais de desgaste excessivo. Verifique o padrão de contato dos dentes para evidências de ajuste incorreto.

-

-

-

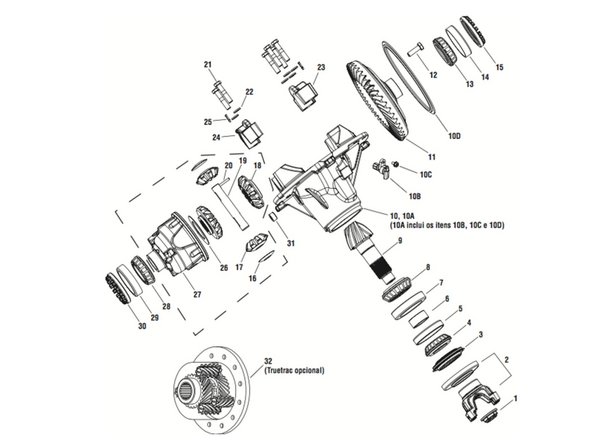

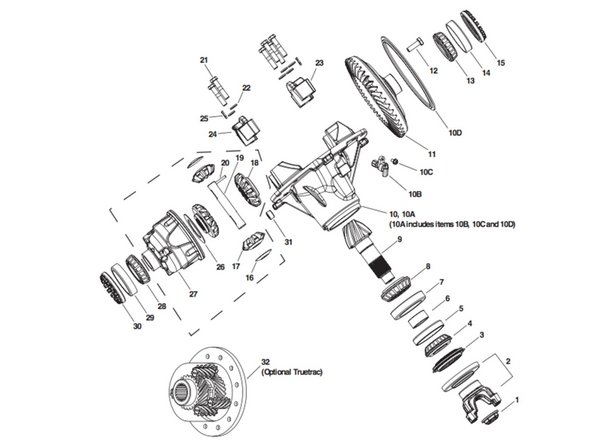

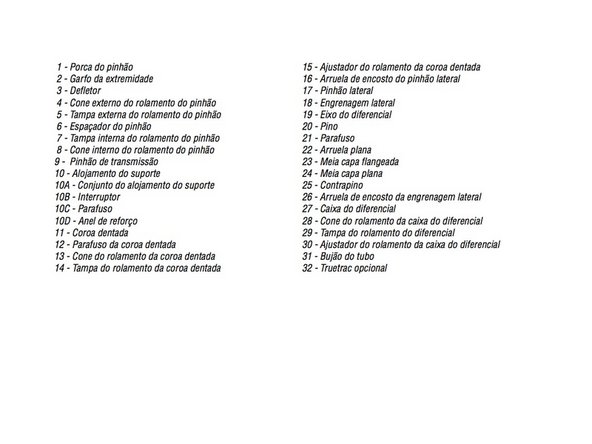

1 - Fixador de suporte

-

2 - Montagem do suporte

-

-

-

Insira tradução aqui

-

-

-

Insira tradução aqui

-

Um agradecimento especial a esses tradutores:

100%

Estes tradutores estão nos ajudando a consertar o mundo! Quer contribuir?

Comece a traduzir ›