Introdução

É bem simples:

- Verifique qual a frequência de lubrificação de acordo com o uso do veículo;

- Use a graxa certa;

- A limpeza é *fundamental*;

- Engraxar;

- Resolver problemas

Peças

-

-

Respeite os Prazos: O primeiro cuidado é respeitar os intervalos de lubrificação.

-

Verifique qual a frequência de lubrificação de acordo com o uso do veículo;

-

Use a graxa certa;

-

A limpeza é *fundamental*;

-

Engraxar;

-

Resolver problemas.

-

-

-

Série 10:

-

Urbano: 10.000 km ou 2 meses.

-

Rodoviário: 20.000 km ou 4 meses.

-

Agrícola e Construção: 5.000 km ou 1 mês.

-

Industrial: 300 horas em uso normal ou 150 horas em uso severo.

-

Caso o cardan fique imerso em água ou lama (ao enfrentar enchentes, atravessar riachos, trabalhar em arrozais, entre outras situações parecidas), refaça a lubrificação.

-

New line.

-

-

-

A maior causa de problemas em cruzetas e juntas deslizantes é a aplicação de graxas erradas.

-

A graxa precisa unir três propriedades:

-

1 - Ser à base de sabão de lítio.

-

2 - Conter aditivos para extrema pressão (EP).

-

3 - Ter o grau de consistência NLGI 2.

-

Não tente economizar usando outro tipo de graxa. O prejuízo com o cardan será bem maior.

-

-

-

Antes de iniciar a lubrificação, é preciso:

-

1 - Limpar e avaliar o estado de conservação das graxeiras de cada cruzeta.

-

2 - Conferir se a engraxadeira não tem restos de graxa velha ou de outro tipo de graxa.

-

3 - Em sistemas pneumáticos, verificar se o ar não está contaminado com água ou óleo.

-

-

-

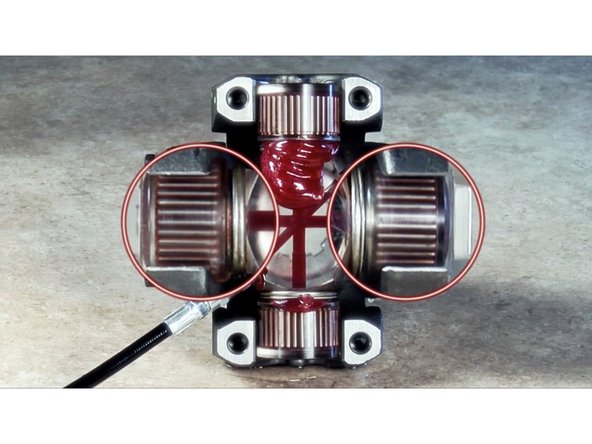

Com tudo em ordem, lubrificar uma cruzeta Spicer 5-12072XS é muito fácil. Mas um cuidado é fundamental: aplique a graxa nova até que a graxa velha saia completamente das quatro capas da cruzeta. Veja no vídeo ao lado o passo a passo detalhado.

-

Siga aplicando até que a graxa nova saia de forma contínua das capas, sem falhas ou bolhas de ar.

-

Se der tudo certo, limpe a cruzeta e o serviço estará pronto.

-

-

-

Se alguma das capas não purgar a graxa velha, você precisa resolver o problema:

-

Primeiro, bata na capa com um martelo de poliuretano e tente lubrificar.

-

Se não resolver, solte as abas de fixação e desmonte a cruzeta na prensa.

-

Veja se os canais internos de lubrificação da peça não estão entupidos.

-

Remonte a cruzeta e, com um torquímetro, aperte as abas com um torque de 40 Nm. Refaça o procedimento de lubrificação.

-

Se mesmo assim a capa não purgar, a única saída será trocar a cruzeta.

-

Cancelar: não concluí este guia.

Uma outra pessoa concluiu este guia.