Introdução

Substituir um Mancal Central Spicer é um procedimento simples, e envolve, 6 etapas: remoção do Cardan, desmontagem da Ponteira Fixa, desmontagem do Mancal Central, instalação do Rolamento e do Mancal Central, montagem da Ponteira Fixa e instalação do Cardan no veículo.

Peças

-

-

Nunca remova o Cardan sem antes certificar de que o veículo está freado ou calçado;

-

Antes de retirar o Cardan, faça marcações dos componentes para garantir o alinhamento, use uma régua se necessário;

-

Para facilitar o trabalho, desmonte o Cardan pela Cruzeta mais próxima ao Mancal Central;

-

Remova as braçadeiras da Cruzeta;

-

Antes de remover o Mancal, solte a porca da Ponteira Fixa;

-

Solte os parafusos que fixam o Cavalete do Mancal ao chassi;

-

Desmonte a Cruzeta da outra extremidade do Cardan;

-

Retire o Cardan do veículo.

-

-

-

Com o Cardan fora do veículo, não use martelos ou marretas de aço para soltar o Terminal de Cardan, impactos podem fraturar as peças. Utilize extrator adequado e caso necessário utilize martelo de poliuretano;

-

Remova o coxim de borracha do Mancal, caso necessário utilize alavanca ou espátula;

-

Caso haja dificuldade em sacar o rolamento, não utilize serras ou talhadeira para cortá-lo, impactos podem danificar a ponteira ou até mesmo desbalancear o Cardan. A utilização de maçaricos ou calor para dilatar o rolamento, também não são indicados, a variação de calor pode gerar empenamento. Utilize um extrator de rolamentos (saca polia).

-

-

-

Limpe bem os componentes e alojamentos antes de montar;

-

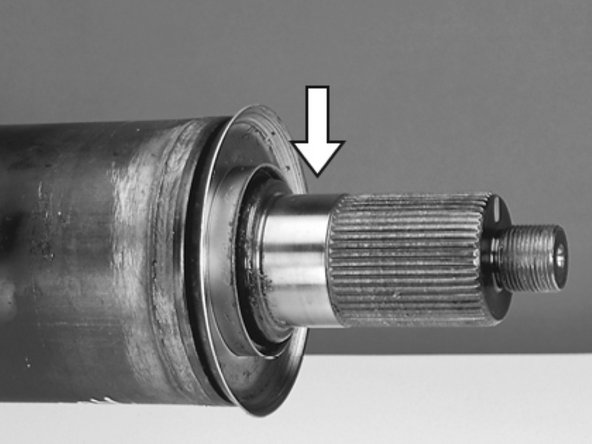

Encaixe o conjunto do Mancal Central manualmente, caso necessite, utilize um martelo de poliuretano para ajustar o posicionamento do rolamento. Monte o mancal central sobre a ponteira do Cardan utilizando extensão tubular apoiando o rolamento pelo anel interno metálico tomando o devido cuidado para não danificar a vedação do rolamento.

-

Coloque o Terminal de Cardan;

-

Posicione a porca e a arruela na Ponteira Fixa.

-

-

-

Observe atentamente as marcações feitas no Cardan para o correto alinhamento;

-

Comece a montagem pela extremidade oposta ao Mancal de Cardan;

-

Instale o Mancal no Chassis e aperte os parafusos do Cavalete. Certifique que o mancal central não ficou deformado após sua fixação. Desalinhamentos podem causar danos ao coxim de borracha do mancal;

-

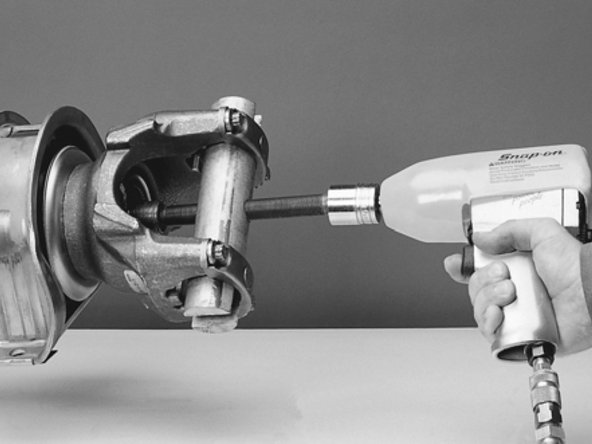

Aplique de 542 a 610 Nm de torque na porca da Ponteira Fixa.;

-

Monte a Cruzeta. Posicione as braçadeiras. Aplique de 162,7 a 183 Nm de torque nos parafusos das braçadeiras.

-

-

-

VERIFIQUE AS MARCAÇÕES PARA GARANTIR O ALINHAMENTO.

-

-

-

Sob quaisquer circunstâncias deve-se tentar qualquer conserto ou manutenção para o qual não foi treinado ou se não possui as ferramentas e equipamentos para o conserto.

-

Sempre use os óculos de segurança adequado quando fizer algum tipo de manutenção. Não usar os óculos de segurança pode resultar em ferimento e/ou perda parcial ou completa da visão.

-

Seja sempre cuidadoso ao trabalhar com produtos que tenham pontas afiadas.

-

A lubrificação inadequada ou o reaproveitamento das peças de acoplamento ou parafusos podem causar a falha do cardan ou até a separação do cardan do veículo. Um cardan separado do veículo pode causar acidente e até mesmo mortes. Não arrisque com a segurança.

-

-

-

Parte importante do trabalho e da própria operação da sua oficina é o descarte correto dos produtos que serão substituídos. Faça a sua parte e juntos contribuímos para um futuro sustentável.

-

Saiba mais em http://www.spicer.com.br/danatureza

-